How Digital Twins Work

Digital twins sound like science fiction, but they are already quietly transforming how industries design, operate, and improve complex systems. At a simple level, a digital twin is a virtual replica of a physical object, system, or process. What makes it powerful is not the model itself, but the continuous connection between the digital and physical worlds. A digital twin does not merely represent reality—it evolves with it, learning from real-time data and reflecting changes as they happen. This capability turns static models into living systems that support smarter decisions and more resilient operations.

- A digital twin works by combining three core elements: a physical asset

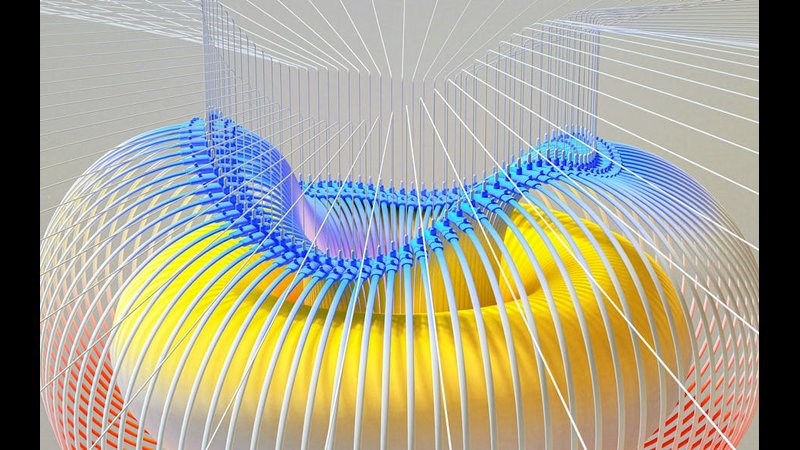

- a digital model, and a data connection between the two. Sensors embedded in physical systems collect data such as temperature, pressure, movement, vibration, or energy use. This data flows into the digital environment, where it updates the virtual model in near real time. Researchers at leading universities describe this feedback loop as the defining feature of digital twins. The virtual model mirrors the current state of the physical system and can simulate future behavior under different conditions.

The technology behind digital twins relies on advances in connectivity, cloud computing, and data analytics. High-speed networks transmit sensor data continuously. Cloud platforms provide the computing power needed to process large data streams and run simulations. Analytics and artificial intelligence interpret patterns, predict outcomes, and identify anomalies. Government research institutions emphasize that digital twins are not a single technology, but an integration of multiple digital capabilities working together. Their value emerges from this integration, not from any one component alone.

One of the most important uses of digital twins is monitoring and prediction. Traditional systems rely on scheduled inspections or reactive maintenance. Digital twins enable continuous monitoring, detecting subtle changes that signal potential failure long before it occurs. In manufacturing, this means machines can be serviced before breakdowns disrupt production. In energy systems, equipment can be optimized for efficiency and longevity. Public research agencies report that predictive maintenance powered by digital twins significantly reduces downtime and operational costs.

Simulation is another core function. Because a digital twin mirrors reality, it can be used to test scenarios without risk. Engineers can simulate extreme conditions, design changes, or usage patterns and observe outcomes in the virtual environment. Universities studying engineering systems note that simulation-based decision-making improves safety and accelerates innovation. Instead of learning through costly trial and error in the real world, organizations learn through experimentation in the digital one.

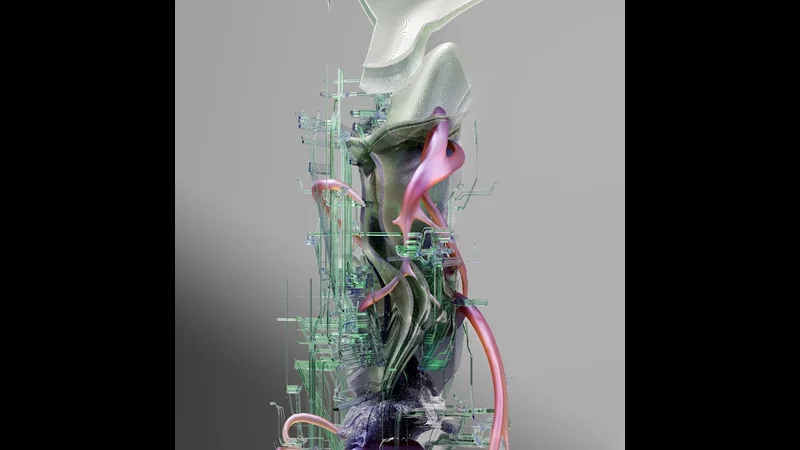

Digital twins are particularly impactful in complex environments where systems interact dynamically. Smart cities use digital twins to model traffic flows, energy consumption, and infrastructure stress. Healthcare researchers use them to model organs or treatment pathways. Aerospace and automotive industries rely on digital twins to design and test vehicles under countless operating conditions. In each case, the digital twin becomes a shared reference point, aligning stakeholders around a single, continuously updated view of reality.

Another important aspect of how digital twins work is lifecycle management. Physical assets evolve over time due to wear, upgrades, and changing usage. A digital twin tracks this evolution, preserving a complete history of performance and interventions. Academic research highlights that lifecycle visibility improves long-term planning and sustainability. Organizations can make informed decisions about upgrades, replacements, and resource allocation based on evidence rather than assumptions.

Artificial intelligence enhances digital twins by adding learning and adaptation. Machine learning models analyze historical and real-time data to refine predictions and automate responses. For example, a digital twin of an industrial system can learn which operating conditions maximize efficiency while minimizing wear. Government technology studies note that AI-enabled digital twins shift systems from reactive to adaptive behavior. The system does not just reflect reality; it actively helps improve it.

Despite their promise, digital twins present challenges. Data quality is critical—poor or incomplete data leads to inaccurate models. Integration across legacy systems can be complex. Security is also a concern, as digital twins often represent critical infrastructure. Federal cybersecurity agencies stress the importance of secure data transmission, access control, and system resilience. Trust in digital twins depends on transparency and robust governance.

Another challenge lies in interpretation. Digital twins generate vast amounts of information, but insight requires skilled human judgment. Universities emphasize that digital twins work best when paired with domain expertise. The technology supports decision-making; it does not replace it. This human–machine collaboration is central to the effectiveness of digital twins.

Looking forward, digital twins are expected to become more granular and more autonomous. Advances in sensor technology, edge computing, and AI will allow digital twins to operate closer to real time and at greater scale. Researchers predict that future digital twins will not only simulate systems, but coordinate them—enabling interconnected twins across supply chains, cities, and ecosystems. This evolution will further blur the line between physical and digital environments.

At a human level, digital twins represent a shift in how people understand and manage complexity. They provide clarity where systems are too intricate to grasp intuitively. They allow experimentation without risk and learning without failure. In a world defined by interconnected systems—from infrastructure to healthcare to climate—this capability is increasingly valuable.

Ultimately, digital twins work because they align technology with reality. They translate physical behavior into digital insight and digital intelligence into physical improvement. As governments, universities, and industries continue refining standards and applications, digital twins are emerging as one of the most practical and transformative tools of digital innovation—quietly reshaping how systems are designed, operated, and improved.

- External Authoritative Sources

- National Institute of Standards and Technology (NIST) – https://www.nist.gov

U.S. Department of Energy – https://www.energy.gov

MIT Center for Advanced Urbanism – https://cau.mit.edu

Stanford Center for Digital Built Environment – https://cdb.stanford.edu

FAQ

What is a digital twin in simple terms?

It is a virtual model of a physical system that updates continuously using real-world data.

How is a digital twin different from a simulation?

A simulation is static, while a digital twin evolves in real time with its physical counterpart.

- Which industries use digital twins most?

- Manufacturing, energy, healthcare, construction, transportation, and smart cities.

- Do digital twins require AI?

- Not always, but AI significantly enhances prediction, automation, and optimization.

Are digital twins expensive to implement?

Costs vary, but many organizations start with targeted applications that deliver clear ROI.

Conclusion

Digital twins work by creating a living digital reflection of the physical world—one that updates continuously, learns from data, and supports smarter decisions. By enabling prediction, simulation, and optimization, they transform how complex systems are managed across industries and public services. As digital infrastructure matures and standards evolve, digital twins are becoming a cornerstone of modern innovation, offering a powerful way to understand reality and improve it responsibly.